Regarding to the drive-in rack, the goods pallet is put on the bracket beam which protrude from the upright frame, forklift can drive into the tray location directly to pick goods which can only be done by FILO rather than FIFO. However, the rack can be designed as drive-through type, i.e. the forklift can work at both end of the rack, storing goods at one end and fetching goods at the other end. So FIFO can be reached. Storage density is higher due to lack of exclusive passage way for the drive-in type rack, but picking good only can be done in a sequence of far or near to the end of the rack, thus each column of rack can only store one sort of goods, it is suitable for the goods strorage of few categories and big quantities.

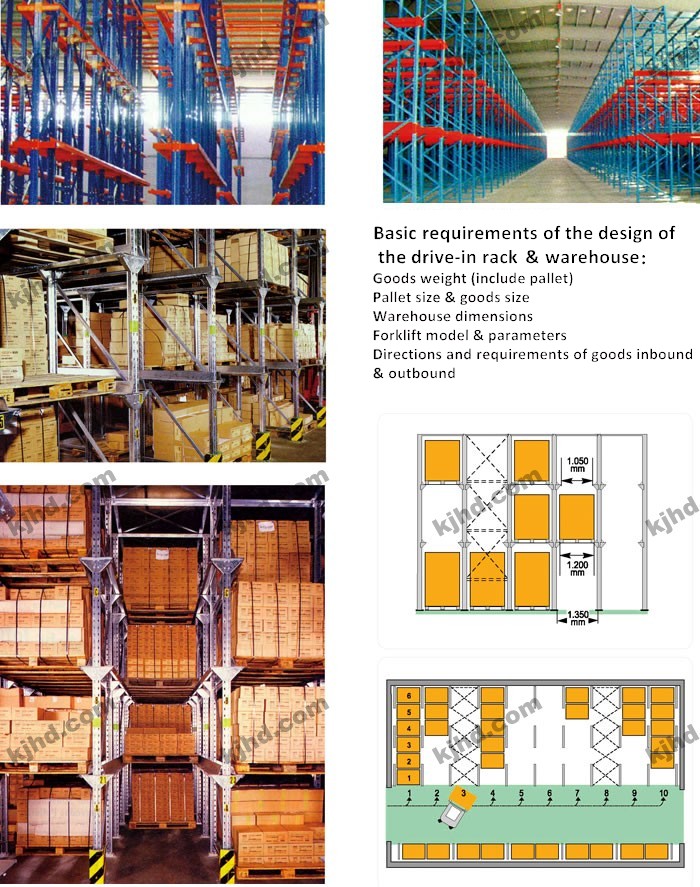

Basic requirements of the design of the drive-in rack & warehouse:

Goods weight (include pallet);

Pallet size & goods size;

Warehouse dimensions;

Forklift model & parameters;

Directions and requirements of goods in-put & out-put of the warehouse.